SAM Food & Beverage

Company Overview

Filtera Bd Ltd is a manufacturer of high-quality cigarette filters. We specialize in producing filters that reduce tar and other harmful substances in cigarette smoke, while maintaining the desired flavor and smoking experience for our customers. Our company has established a strong reputation for producing reliable and effective cigarette filters. Our team of experienced professionals is dedicated to delivering the best possible products and services to our customers, and we are committed to continuous improvement in all aspects of our business.

Our mission is to provide smokers with a safer and more enjoyable smoking experience, while contributing to a healthier environment. We believe that our products can make a positive impact on the lives of our customers and the wider community, and we are committed to sustainability and social responsibility in all of our operations.

Our Equipment and Machinery

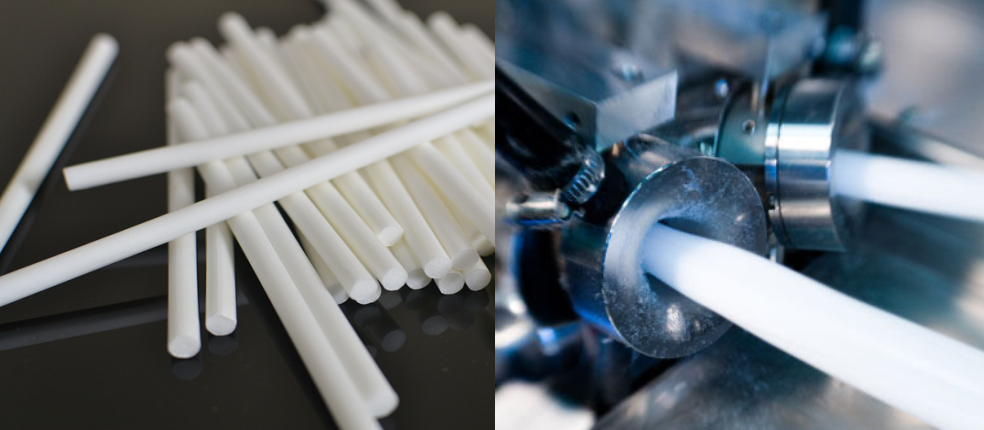

Our factory houses the sophisticated KDF-2 filter maker made by Hauni GmBH. The machine was purchased directly from Hauni and has been in production since 2012 providing filter making support for large cigarette manufacturers. Currently only four cigarette manufacturers have a KDF 2 for their filter manufacturing needs. The KDF-2 is a very reliable machine capable of producing Filters at a speed of upto 400m/min. The KDF-2 is highly versatile and capable of making regular king size filters, slim filters and super slim filter rods. Furthermore, with simple attachments, it can be configured to manufacture menthol filament and capsule filters as well Our international standard factory is based in Tongi, Gazipur and is an hour’s drive from Dhaka city. We have a completely temperature / humidity controlled environment which results in the best quality output. With a trained and highly experienced team, we can deliver outstanding quality at reasonable prices.

Filter Rod Manufacturing Process

Cigarette filter rod manufacturing is a process that involves producing the

filter component of a cigarette. The filter is made from a material that traps

some of the harmful substances in cigarette smoke before it enters the

smoker's lungs.

The manufacturing process typically involves the following steps:

- Spinning: The raw material for the filter, typically cellulose acetate, is dissolved in a solvent to create a viscous solution. This solution is then extruded through small holes in a spinning machine to create long filaments.

- SCutting: The filaments are then cut to the desired length using a cutting machine. The length of the filaments determines the length of the filter.

- Assembly: The cut filaments are then assembled into a cylindrical shape using a filter assembling machine. The machine compresses the filaments together to create a dense filter.

- Drying: The assembled filters are then dried to remove any remaining solvent.

- Quality control: The filters are then inspected for quality, with any defective filters being discarded.

- Packaging: The filters are then packaged and shipped to cigarette manufacturers.

It's worth noting that some cigarette manufacturers use different materials for their filters, such as charcoal or cotton. Additionally, some manufacturers produce filters that are not cylindrical, such as those with a conical shape.

Capsule Filter Rod Manufacturing Process

There are several parameters that are used to measure the quality of cigarette filter rods, including:

- Pressure drop: This is a measure of the resistance of the filter to the flow of air. A high pressure drop indicates that the filter is effective at trapping particles, but may also make the cigarette harder to draw.

- Efficiency: This measures the percentage of particles that are removed by the filter. A higher efficiency indicates that the filter is better at removing harmful substances from the smoke.

- Length and diameter: The length and diameter of the filter rod can affect the amount of smoke that is drawn through the filter and the level of filtration.

- Physical properties: The physical properties of the filter material, such as stiffness and tensile strength, can affect the filter's effectiveness and its ability to withstand processing and handling.

- Appearance: The appearance of the filter rod can be an important factor in determining quality. The filter should be uniform in color, shape, and size, with no visible defects or irregularities.

- Chemical properties: The chemical properties of the filter material, such as its ability to absorb or adsorb substances, can affect the filter's effectiveness.

- Flavor and odor: The filter should not impart any unpleasant flavors or odors to the smoke.

Manufacturers typically have specific quality control procedures in place to ensure that these parameters are measured and maintained within acceptable limits.

PRESSURE DROP TESTING

Pressure drop is typically measured using a device called a pressure drop

tester. The pressure drop tester measures the resistance of the filter to the

flow of air by measuring the difference in pressure between the upstream and

downstream sides of the filter.

Here are the general steps involved in measuring pressure drop:

- Prepare the filter: The filter to be tested is placed in a holder and clamped securely in place

- Set up the tester: The pressure drop tester is set up with a flow meter and pressure sensors on the upstream and downstream sides of the filter.

- Calibrate the equipment: The equipment is calibrated to ensure accurate readings.

- Conduct the test: Air is drawn through the filter at a specified flow rate, and the pressure difference between the upstream and downstream sides of the filter is measured. This pressure difference is recorded as the pressure drop.

- Repeat the test: The test is repeated several times to ensure consistent results.

The pressure drop measurement can be used to determine the effectiveness of the filter at trapping particles. However, it's important to note that a high-pressure drop can also make the cigarette harder to draw, which can be a negative factor for consumers. Therefore, manufacturers must strike a balance between filtration efficiency and ease of draw.